- +45 8693 1333

- juhl@juhl-as.com

- Monday - Thursday: 8:30 - 16:00. Friday to 15:00

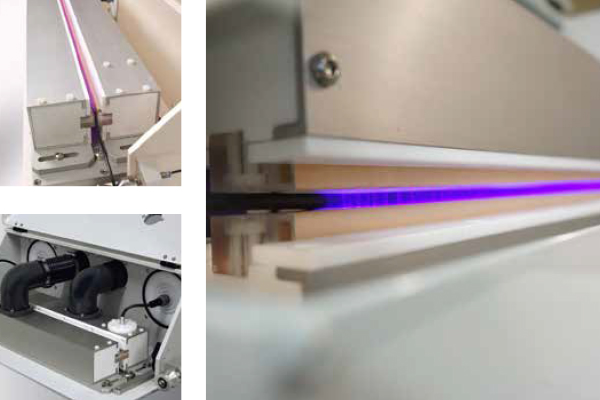

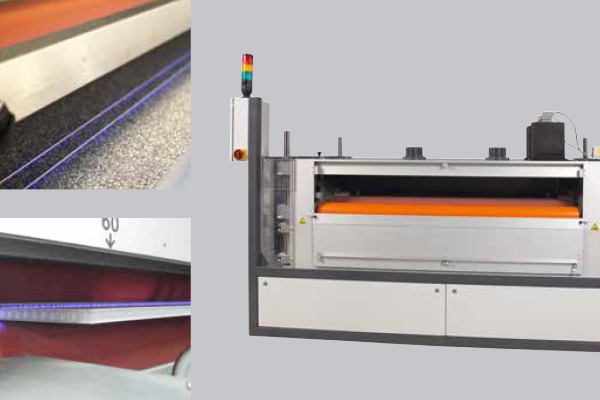

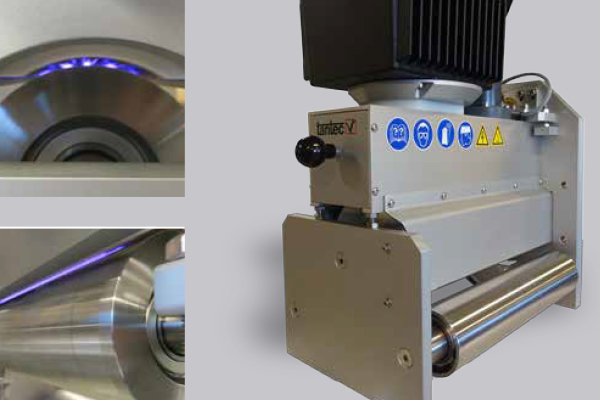

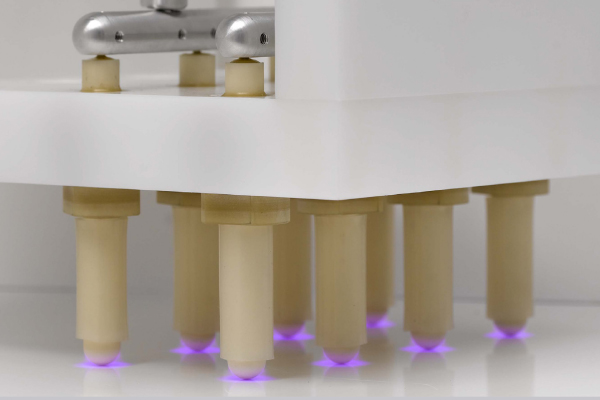

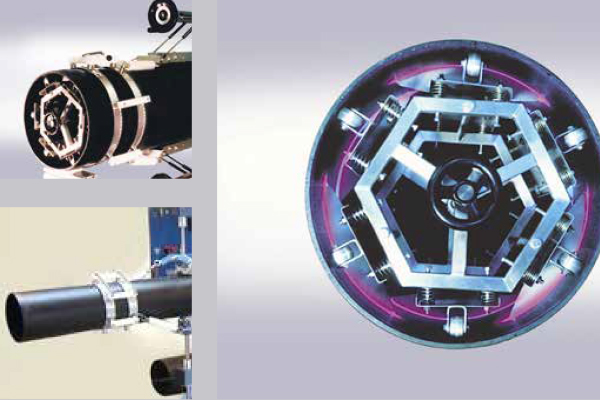

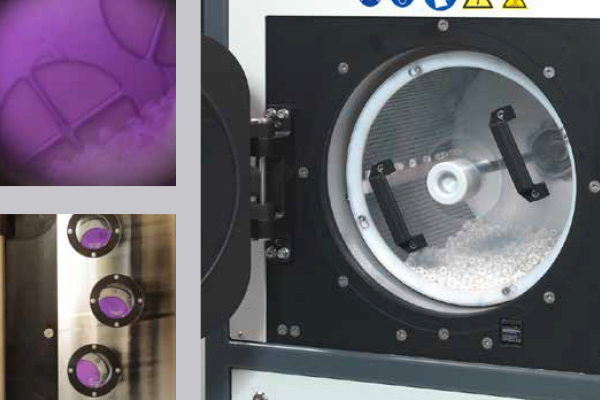

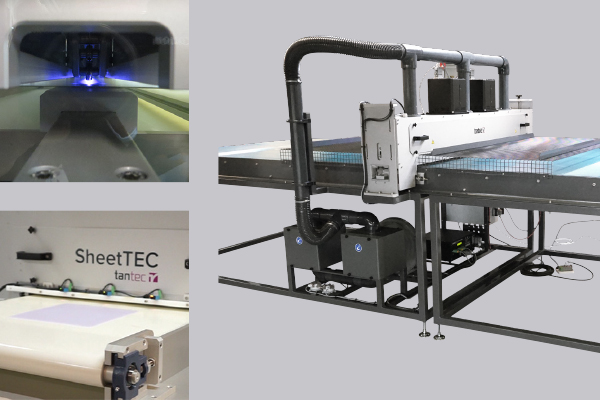

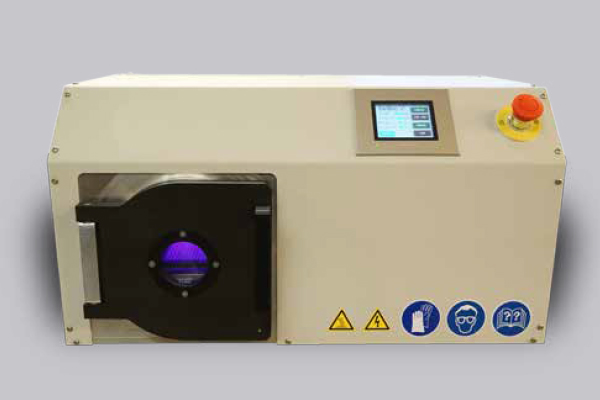

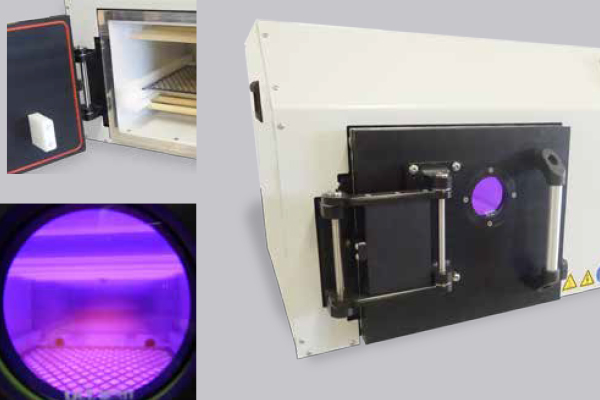

Tantec has a long well know experience in solving the problems of adhesion. Improved quality for printing, coating, bonding, wetting, painting, and cleaning. The Tantec core competence is manufacturing quality, high-end surface treatment products for our industry. Tantec continuously develops new innovative solutions for a demanding market. This makes the perfect match with the decoration, marking and identification portfolio from Juhl.